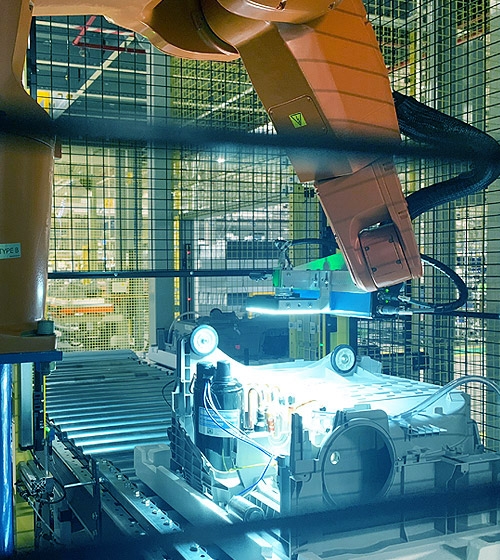

The purpose of the robotic inspection station, based on a multi-camera vision system, is to verify the correctness of manufacture and assembly of the system of copper pipes that are part of the heat pump.

The system first verifies the placement of the copper tubes. For the heat pump to function properly, it is important that the tubes that comprise it are at the correct distance from one another and from the other components of the pump. Through the use of a 3D camera, the system is able to control the position of the tested elements in space. The next stage is to verify the tightness of the soldered joints. The pump installation is filled with technical gas and it is important to maintain its tightness. The vision system determines the points to which the robot directs the tool that collects an air sample from around the joint of copper elements for analysis.